In combination with the primary report, an function log, including any warning messages produced over the execution from the macro, may additionally be manufactured.

So, for regime cleaning, an argument can be manufactured that visually cleanse could possibly be the only criterion for last machines launch, As a result eliminating the need for swabbing and tests (periodic monitoring should be wanted). Exhibiting each of the calculations makes the ultimate selection robust and defendable.

The ECA presents various totally free GMP newsletters for which you'll be able to subscribe to Based on your preferences.

The literature features, with some nuances, a good deal of information on strategies to identify the marker compound and compute MACO. The strategies presently Utilized in the industry are different, and occasionally disjointed, and may from time to time involve knowledge resources and modes of calculations that are incorrect or unverifiable. The lack of a reputable validated procedure can promote the overuse of “visual clear” (devices dried and freed from obvious dirt around the floor) as the only criterion for machines release following cleaning.

The Performing get together would usually include the subsequent personnel customers, preferably Individuals with a fantastic Perception into the organization's Procedure.

If 1 cleaning procedure has become shown for being adequate for a variety of goods, then it is just needed to have one cleaning SOP for all those solutions for each piece of apparatus. Cleaning processes ought to be adequately in depth to remove the potential for any inconsistencies over the cleaning approach check here [seven, 8].

It's not our intent Within this paper to dive deeply in the history from the MACO evolution, but a quick dialogue is necessary to apprise readers of the criteria adopted for threat score and identification of your marker compound.

The thought “Check-Right until-Clean” will be applied. This idea includes cleaning, sampling and screening with repetition of this sequence till an acceptable residue Restrict is attained.

The APIC Assistance refers read more largely to ADE from the samples of calculations A part of this chapter, in line with the ISPE advisable calculations.

Upload the PDF file you would like to operate with using your digital digicam or cloud storage by simply clicking on the + icon.

No, at the very least I did not uncover a single even the time period devoted gear is widely Employed in regulatory documents.

Pharmaguideline is actually a pharmaceutical blog site where pharmaceutical principles are stated in very simple and easily easy to understand language for industry experts and pupils. All article content and SOPs are penned by Ankur Choudhary.

The development, execution, and validation of your CVLM offers a reputable tool to simplify and automate the cleaning validation calculations to support a compliant cleaning validation software.

It is thought these days, due to the fact You can find have to have to keep up quality, regularity and above all community basic safety. Validation can be a immediate developing and evolving matter. More than a past 15 several years, machine automation and approach Handle while in the pharmaceutical sector has induced added problems relating the validation with the processing methods.

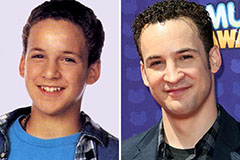

Ben Savage Then & Now!

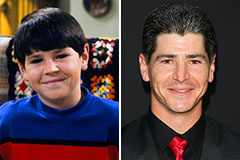

Ben Savage Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Mike Vitar Then & Now!

Mike Vitar Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now!